See deeper, solve smarter—advanced insights for reliable pump and VFD operation.

Struggling with system issues? Our advanced diagnostics and expert troubleshooting quickly identify and resolve problems to keep your operations running smoothly.

Your pump systems deserve more than guesswork—

At GarigITS, we go beyond standard troubleshooting to provide advanced diagnostics that keep your equipment running at peak performance. Our expertise includes ultrasonic pipe inspections, ultrasonic flow testing, laser alignment, and vibration analysis—cutting-edge techniques that allow us to detect inefficiencies, pinpoint hidden issues, and prevent costly failures before they happen. Whether it’s ensuring precise shaft alignment, optimizing flow rates, or identifying early signs of wear and tear, we deliver data-driven solutions that improve reliability, extend equipment life, and minimize downtime. When accuracy matters, trust our expertise to keep your systems running smoothly.

Our Services

-

Inspections

Ensure reliability and system performance for your equipment with inspection programs that build a precise picture of current, trending, and predictive data points that take the guesswork out of system maintenance. Know when and where failures are going to occur and eliminate unplanned system downtime.

-

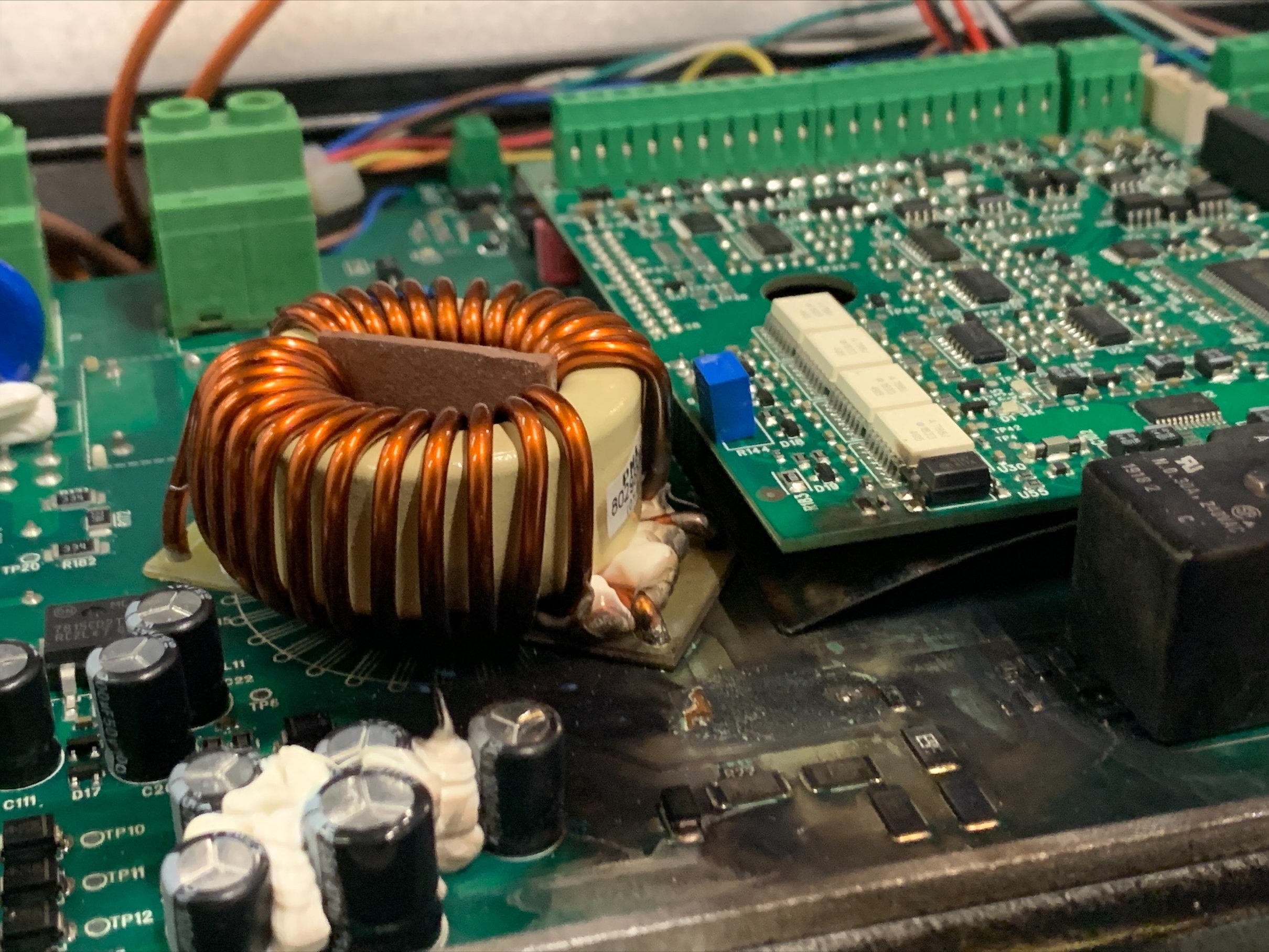

Diagnostics & Troubleshooting

Minimize downtime and get your system back online fast with our advanced diagnostics and specialized tools. We focus on variable frequency drives, motors, and pump systems-using expert troubleshooting techniques to quickly identify and resolve issues with precision, so your operation stays efficient and reliable.

-

Repair

Don't waste money on unnecessary replacements-our expert repair services quickly restore your drives and control panels to full functionality. With fast diagnostics and precision repairs, we get your system running again at a fraction of the cost of a full replacement.

-

Ultrasonic Flow Testing (UFT)

Effortlessly assess system performance, detect flow-related issues, and reconstruct curves for existing pumps without the need for interruptions or shutdowns.

-

Vibration Testing (VBT)

Monitor equipment health through vibration analysis to detect issues early. This proactive approach identifies misalignments, bearing wear, and imbalances, enhancing efficiency and reducing downtime.

-

Ultrasonic Thickness Testing (UTT)

Monitor the thickness and corrosion buildup within system piping to ensure overall integrity, efficiency, and reliability of the piping system throughout its operational lifespan.

-

Precision Laser Alignment

Extend equipment lifespan and reduce vibration and wear through precision pump alignment. Addressing alignment issues boosts pumping system performance, lowers maintenance costs, and optimizes productivity.

Let’s work together.

Interested in working together? Fill out some info and we will be in touch shortly! We can't wait to hear from you!